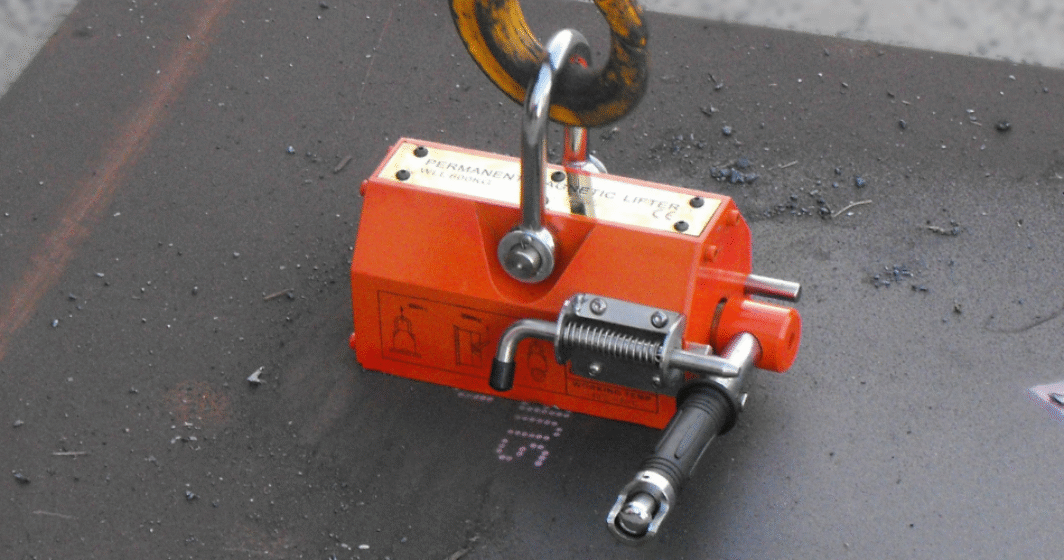

Preventing Hand Injuries with the Right Lifting Magnet Technology

Reducing back, hand and wrist injuries is a top priority for many industrial and manufacturing companies. At MSA Magnetics, we understand that choosing the right lifting magnet can make a significant difference in workplace safety, especially when it comes to preventing lacerations, crush injuries, and strain caused by manual handling.

Why Active Shunting Magnets Improve Safety

One of the most effective ways to reduce hand injuries is by using Active Shunting Magnets. These magnets feature a more controlled and gentler actuation compared to traditional Deep Field Passive Shunting Magnets, which can be forceful and difficult to operate, especially when used outside their optimal magnetic saturation range.

For example, a 3-tonne Passive Shunting Lifting Magnet is not rated for use below 30mm material thickness and performs best in the 50mm–80mm range. Operating outside this range can lead to excessive force requirements and increased risk of injury.

Zero Residual Magnetism = Safer Handling

Another key safety advantage of Active Shunting Lifting Magnets is their zero residual magnetism. This feature eliminates the need to manually clean swarf, grit, or metal fragments from the magnet’s surface between lifts—significantly reducing the risk of laceration-type hand injuries.

Residual magnetism in traditional magnets can cause debris to cling to the magnet face, requiring manual removal and increasing the chance of cuts and abrasions.

Lifting Thin Materials? Choose Carefully

If your application involves lifting materials less than 10mm thick, be cautious. Many Passive Shunting Magnets are not rated for thin materials due to two main issues:

- Excessive handle force: Operating the magnet requires so much force that it can damage the magnet or strain the operator.

- Flux inefficiency: Much of the magnetic flux is wasted below the sheet, reducing lifting performance and increasing the risk of unsafe handling.

For thin sheet metal, Active Shunting Magnets are often the better choice due to their precision and efficiency.

De-Stacking Sheet Metal Safely

When lifting sheet or plate metal from a stack, using a Shallow Field Magnet can help prevent picking up multiple pieces at once. This improves safety and efficiency, especially in high-volume operations. Selecting the right magnet field depth is essential for safe de-stacking and accurate single sheet lifting.

Protecting Sensitive Materials from Damage

If your materials require careful handling to avoid scratches or surface damage, Active Shunting Magnets with zero residual magnetism are ideal. These magnets release cleanly without dragging or sticking, preserving the integrity of polished or coated surfaces.

Watch our video on residual magnetism to learn more about how this technology protects your materials and your team.

Handling Billet or Thick Steel (40–80mm+)

For lifting heavy billet or thick steel, Passive Shunting Magnets are often the preferred solution. They excel in this range and offer robust performance. However, it’s critical to ensure the magnet includes a two-action safety control to prevent accidental discharge—this is a requirement under Australian safety standards.

Unfortunately, we continue to see magnets for sale in Australia that do not meet this standard. Always verify compliance before purchasing.

MSA Magnetics: Your Partner in Safe Lifting Solutions

At MSA Magnetics, we’re not here to play favourites. We proudly recommend both our Passive Shunting Pro-Lift range for their durability and reliability, and the Active Shunting Magswitch products for their advanced technology and versatility.

Whether you’re lifting thin sheet metal, handling sensitive materials, or working with heavy steel, we’ll help you choose the right lifting magnet for your application safely and cost-effectively.

Contact MSA Magnetics today for expert advice on selecting the best lifting magnet for your needs.