MSA Magnetic Head Pulley Conversion

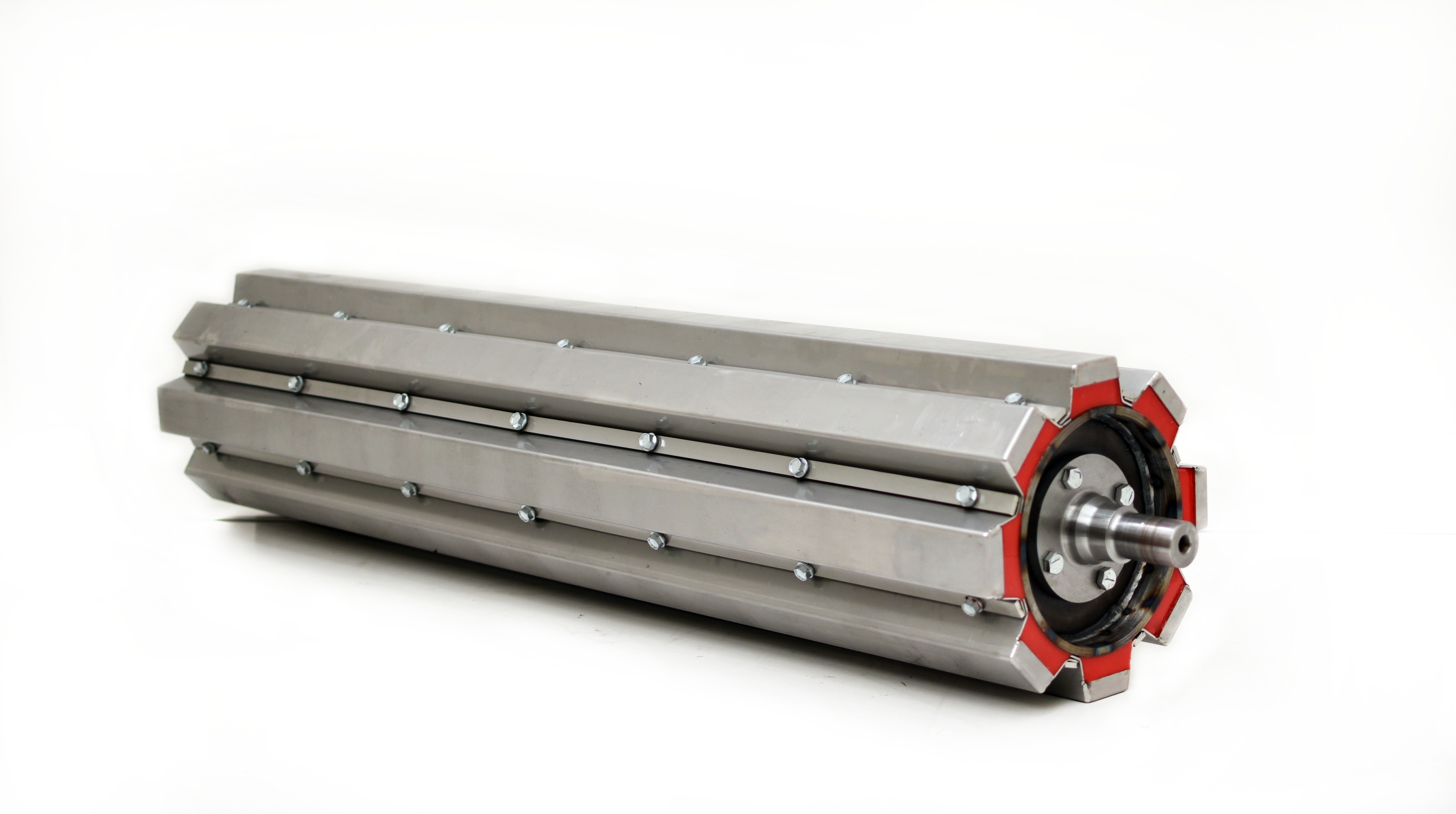

MSA Rare Earth Magnetic Pulley Lagging sets the global standard for magnetic performance—delivering up to twice the strength of competing systems. Our RE80® Magnet Conversion System upgrades your existing head pulleys into high-strength magnetic pulleys for automatic tramp iron removal. Save costs by converting your own pulley, or choose a complete new magnetic head pulley solution.

Price:

Overview

Magnetic Head Pulleys – Efficient Metal Separation

Conveyor systems rely on multiple pulleys to move material, including head (drive), tail, take-up, and bend pulleys. Head Pulleys, located at the discharge end, provide the driving force for the belt.

In industries like mining, recycling, and resource recovery, removing tramp iron and ferrous metal from the product stream is critical. MSA Magnetic Head Pulleys offer a robust, automatic solution for continuous separation at moderate belt speeds—improving product purity and protecting downstream equipment.

How They Work

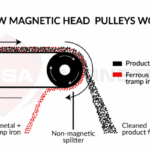

Magnetic Head Pulleys function like standard pulleys but attract ferrous metals as material reaches the discharge point.

- Non-magnetic material follows its normal trajectory

- Ferrous metal stays on the belt until it exits the magnetic field, then drops into a separate chute or bin

- Common contaminants removed: nails, bolts, wire, cans, screws, tools

Optional non-magnetic splitters can further separate discharge streams.

FEATURES

- Effectively removing nails and metal pieces from woodchips and pallet grinding

- Popular in recycling plants and quarries

- Protection of crushers

- Protection of paper shredders

- Ideal as secondary complimentary magnet down stream of overbelt/suspension magnets

- Assists with conveyor belt tracking

- High Energy Rare Earth Magnets—standard & maximum super high strength options

- Small increase in diameter & weight of pulley

- A low cost option to the purchase of new, conventional magnetic pulley types

Product Models

| Product | Add to cart or quote buttons | |

|---|---|---|

| ||